NASPA Purlin

CEE & ZED PURLIN�Special designed and developed for structural applications, lightweight structural steel members which sections are accurately roll-formed from high strength coated steel in accordance with the provision of AS/NZS 4600:1996 Cold Formed Steel Structures.

NASPA Cee PURLIN

Sections may be used in single spans and unlapped

continuous spans in construction with the purlins butted at internal support. It is ideal as wall purlins and eave purlins or where compact sections are required for detailing.

NASPA Zed PURLIN

Sections with one broad and one narrow flange are designed to nest neatly and are intended for lapping at the internal supports. It may be used over single spans, unlapped and lapped continuous spans in construction. Lapped continuous spans result in a considerable capacity increase in the system.

คุณสมบัติ (Specifications)

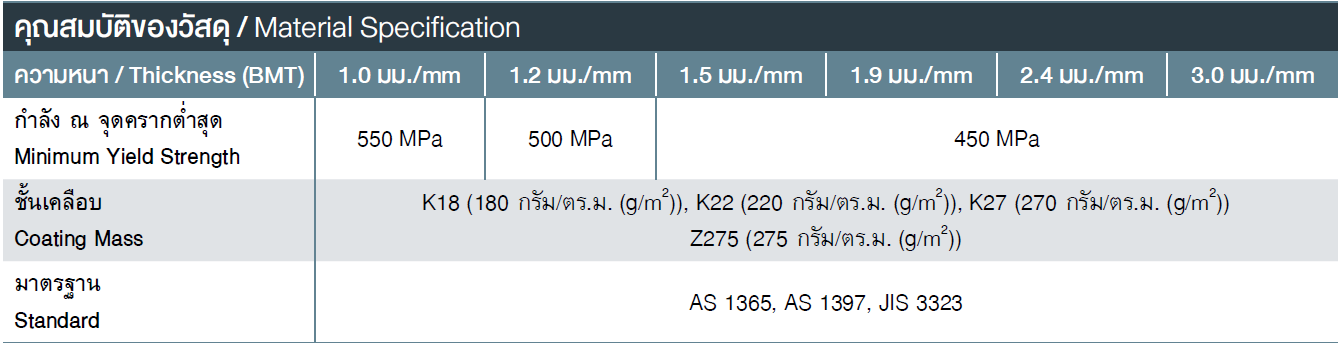

แปตัว C และตัว Z มีทั้งชนิดที่เคลือบสังกัสี Z275 และซุปเปอร์ไกม่า K18 โดยวัสดุที่ใช้มีค่า Minimum Yield Strength ไม่ต่ำกว่า 450 MPa โดยมีความหนาตั้งแต่ 1.00 มม. – 3.00 มม. ให้เลือกใช้ตามความเหมาะสม

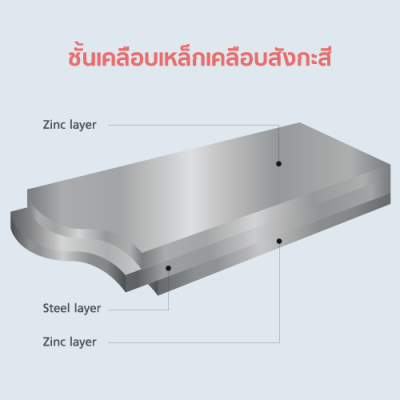

เหล็กเคลือบสังกะสี (Galvanized) Z275 G450

Manufacturing by using steel with Minimum Yield Strength not less than 450 Mpa through continuous hot dip galvanized process (Zn). Z represents thickness of both sides in square meter. Z275 is meaning to total coating mass of Zinc on both sides not less than 275 gram per square meters. Coating Zinc has acted as the shield of steel surface in reaction against atmosphere. Zinc is still having key eroded protection property in SACRIFICIAL format by scarifying itself on behalf of steel that help preventing rush on the cutting edge which is the easy corrosion part. Suitable for general steel works. purlin, buildings structure and factories construction,�

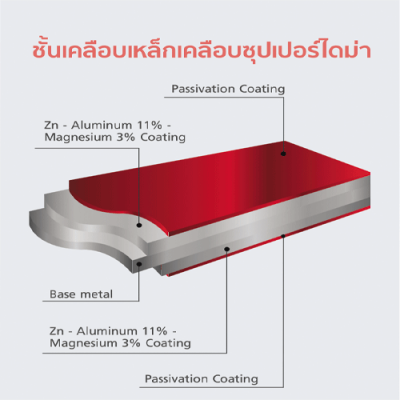

SuperDyma ® Steel

Manufacture by continuous hot dip process,�base metal is high tensile steel. Yield strength is at�300 MPa, 450 MPa, 500 MPa and 550 MPa. (G 300 ,G�450 , G 500 , G 550 ). K symbol representing both�sides coating thickness in gram per square meter�i.e K 18 , K 22 , K 27 refer to coating mass of both�sides not less than 180 , 220 and 270 gram�per square meter respectively.�SuperDyma ® make�a significant contribution to architectural�material and is highly valued for its high corrosion�resistance and usability in all weather. Suitable for�use as structures such as residential structures,�prefabricated truss (purlins), girts and wall studs�etc.